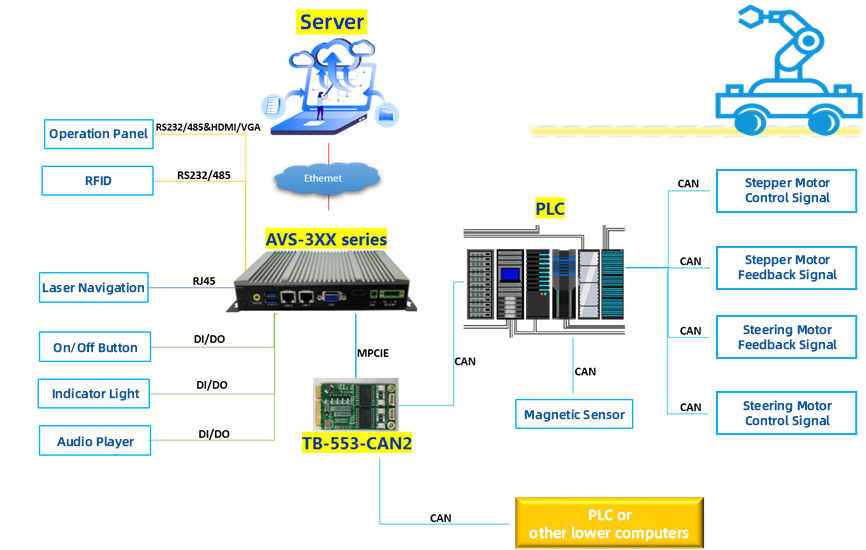

As we are in the Industry 4.0 era, there are more and more companies using semi-automated and fully automated system. In the logistic industry, the most widely used application is for intelligent assembly, intelligent picking and intelligent carrying.

AGV represents Automated Guided Vehicle, which can follow the regulatory route and has various functions, including moving load and equipping with safety device. AGV can accomplish automated logistics management by combining WMS and MES. However, AGV robot has successfully changed the working system from person-to-goods to goods-to-person. This advanced manufacturing procedure, can highly increase the working efficiency and lower the labor cost.

l advantages

1. Support vertical AI system, machine vision, edge computing, machine learning and machine reasoning.

2. Support DDR3L SO-DIMM 1333MHz up to 8GB.

3. Support 1 x 2.5” SATA2 HDD space

4. Fanless design

5. Support wide range DC 9~36V power input and POE

6. Flexible expansions with Mini PCIe slot